VNAs for Materials Measurement

Perfect for Lab and Field Testing

Our VNAs are used for a variety of materials measurement applications. From NASA estimating fuel levels in the fuel tank with 1-Port reflectometers to Compact and Cobalt analyzers incorporated into portable, table-top free-space measurement systems that take materials RF measurement out of the lab and into the field or manufacturing environment to measuring moisture and sugar content in crops, liquid level in bottles of soft drinks and other food quality parameters using microwave sensor systems.

Materials Measurement Integration

Compass Technology Group (CTG) is focused on taking innovative materials measurement research to product. CTG integrates Copper Mountain Technologies’ network analyzers into their systems with probes. Their systems include conventional and advanced measurements, such as free space, resonant cavity, and waveguides.

Compass Technology Group (CTG) & Copper Mountain Technologies (CMT) have developed advanced microwave sensor systems for non-contact measurements to monitor real-time / in-line quality of packaged food.

AMMP Spot Probes

Compass Technology Group develops and utilizes specialized probes that enable the measurement of materials in a number of unique environments. CTG’s recently developed spot probe technology called Advanced Microwave Mapping Probes (AMMP) is a significant improvement over traditional dielectrically loaded horns due to optimized metal radiating elements, dielectric loading, and shape. The spot probes are specially designed antennas encapsulated in a dielectric and optimized to provide a small illumination spot 3 to 8 cm in front of the probe.

This Comparison of Materials Measurement Accuracy of RF Spot Probes to a Lens-Based Focused Beam System weighs the performance of CTG’s AMMP Spot Probes against the well-established free-space focused beam technique for microwave characterization of materials.

Take an in-depth look at the AMMP Spot Probes available from CTG.

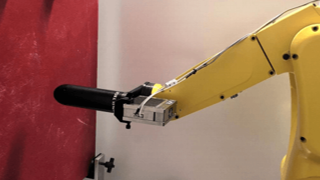

Custom AMMP Measurement Systems Featuring CMT VNAs

Compass Technology Group has developed several custom measurement solutions that feature their AMMP Spot Probes in combination with a CMT VNA to tackle complex measurements.

Handheld System

This portable, handheld reflectometer system is suitable for point inspection of RF coatings and materials. This system provides 2-18 GHz surface reflectivity measurement using CTG’s RF spot probe technology. This system integrates with a 1-port VNA from CMT, eliminating the RF cable and enabling faster, more reliable measurements.

Microwave Calipers Measurement System

This lightweight and adjustable fixture secures wideband 2-20 GHz probes at the proper alignment and distance for optimal measurements. It is versatile and easy to use with multiple specimen types and sizes. The RF spot probes can even be removed and used as hand-held measurement devices on specimens that are too large to fit in the largest setting. This system extends the application capabilities from the lab where a tabletop setup is likely the best option, to include the production setting where the user may want QA measurement capabilities for oddly shaped, sized, and positioned DUTs.

Materials Measurement

SPEAG’s electromagnetic antenna products are compatible with Copper Mountain Technologies instruments. SPEAG’s mission is to expand and strengthen its position as the leading developer and manufacturer of the most reliable, efficient, user-friendly, and advanced numerical tools and instrumentation for the accurate evaluation of electromagnetic near- and far-fields from static to optical frequencies.

DAK – Dielectric Assessment Kit Product Line

What are DAK, DAKS, and DAK-TL?

The Dielectric Assessment Kit (DAK) product line offers high-precision dielectric parameter measurements (permittivity, conductivity, loss tangent) over the very broad frequency range from 4 MHz to 67 GHz for applications in the electronic, chemical, food, and medical industries. The product line consists of 1) DAK single probes solutions, 2) DAK Systems, and 3) DAK-TL-P the first system ever able to measure thin-layer materials and small volumes of liquids.

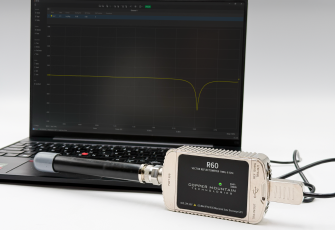

DAKS is based on the same probe technology as the single probe DAK versions but with the vector reflectometer integrated to eliminates phase distortions due to cable movements, i.e., the probes are moved to the object under test; with a single probe, the probe and cable must remain stationary, which can complicate certain measurements.

Currently, two versions of DAKS are offered:

DAKS-12: 4 MHz – 3 GHz, with integrated with the R60 1-Port VNA

DAKS-3.5: 200 MHz – 14 GHz with integrated with the R140 1-Port VNA

See other SPEAG materials measurement solutions.

SWISSto12 supplies next-generation Radio Frequency (RF) antenna, waveguide, filter, and integrated subsystem products. Products are used for satellite telecommunications, space equipment, radar, remote sensing, and test & measurement applications.

The Material Characterization Kit (MCK) is a perfect solution for dielectric material characterization in mmWave frequencies. The MCK allows dielectric properties to be measured reliably, quickly, and conveniently.

The solution covers the ranges from WR-28 to WR-1.0. The kit includes the MCK device, calibration short, screws to connect the waveguide adapters, and a protective Pelican case. It was developed for solid samples, but there are solutions for soft materials, foam, liquids, powders, coated materials, and multilayer materials.

The benefit of Copper Mountain Technologies VNAs and Frequency Extension System is that time domain is included standard in the software.

Permittivity error εr ± 2%

Loss tangent error tanδ ± 10%

- Reflection < -20dB

- Mode purity 98%

- Plug and play solution

- Two-click calibration

- One-click measurement

- No sample preparation

- Repeatable results

- Broadband solution

- Self-aligned sample position

- Swiss made