Sonomatic performs a wide array of non-destructive tests on non-metallic materials such as fiberglass and polyethylene piping. These materials are used for gas, water, fracking, and additional areas where conventional testing techniques are inadequate. Featuring a frequency range of 85 MHz to 14 GHz and a measurement speed of 200 µs, the performance of Copper Mountain Technologies’ R140 1-Port VNA, coupled with its small size, make it the perfect instrument to address Sonomatic’s unique needs. Most notably, they determine the proficiency of critical welds on large sections of plastic pipe that are used to transfer contaminated water. Sonomatic has made complex tasks like this one more manageable with the use of the R140 network analyzer.

Sonomatic is a worldwide organization with expertise in ultrasonic inspection design, development and application, dating back more than 30 years. Sonomatic’s largest client base is in the oil and gas industry where they design and develop innovative inspection methods that are applied by a team of experienced field service engineers. Today, the company has widened its focus and provides proven yet pioneering services to customers in defense and power generation.

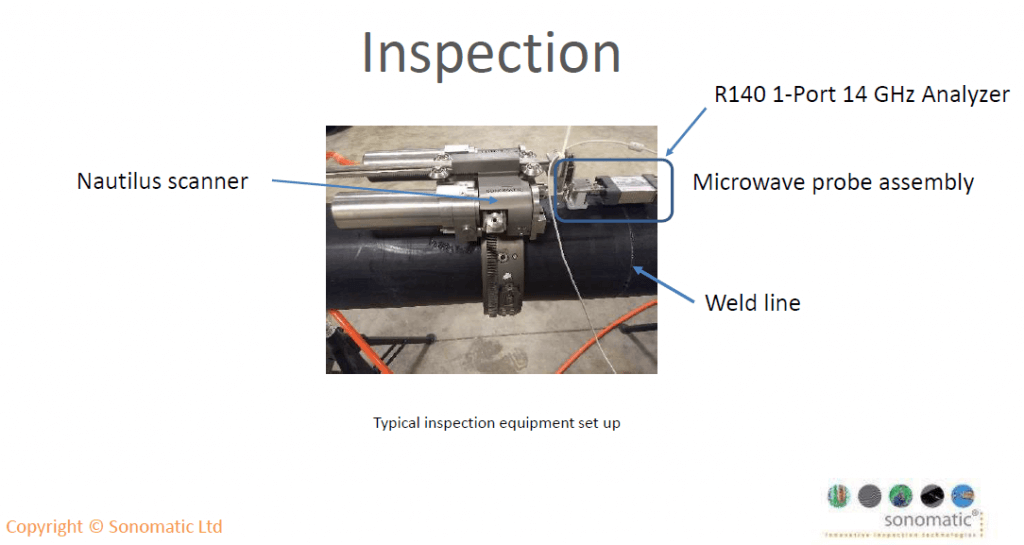

Sonomatic utilizes a small robot that clamps onto a device under test (DUT), then drags the waveguide across the DUT, a polyethylene pipe for example, and eventually scans the full surface of the object. Previously, Sonomatic was forced to mount a larger VNA onto the body of the scanner and connect it to a coaxial waveguide adapter with cables. This method was flexing and destroying expensive cables, requiring them to be replaced frequently. CMT’s R140 simplifies this process. It connects directly to the waveguide, eliminating the cost of replacing cables. “I don’t notice it’s there; I just get on with my job,” said Donald McNicol, Microwave Division Manager at Sonomatic. “The most difficult part is turning the instrument on”.

An issue arose when Sonomatic’s assembly was dropped, resulting in a broken Micro-USB connector on the VNA. Upon speaking to Copper Mountain Technologies’ service department, Donald was informed of his options moving forward. Ultimately, the instrument was replaced through a simple and concise process, allowing him to quickly return to work without the hassle of waiting for the VNA to be repaired.

Sonomatic tests plastic pipes to move contaminated water from well to well, this can require the transfer of up to 30,000,000 gallons of water. Traditionally, trucks have been used to move these large quantities of water. This is time consuming and expensive. Operators have begun creating large rings of piping as an efficient alternative for transporting the water. The integrity of the welds for this piping is critically important because any amount of leakage is troublesome and may result in substantial fines or even jail time. Methods such as X-Ray and ultrasound have proven to be ineffective for evaluating the success of these welds. To address this issue Sonomatic has begun using the R140 VNA to validate weld integrity in the pipes.

The use of ‘U’ wave signals allows Sonomatic to detect differences in the dielectric constant of the material. Based on the molecular structure of the plastic and the changes in dielectric at the weld site, they can determine the proficiency of the welds. Before the advent of small, portable VNAs, such as the R140 1-Port 14 GHz analyzer, it was impractical to evaluate welds for this type of plastic pipe.

The R140 has ultimately simplified Sonomatic’s testing process, while eliminating unnecessary costs and enabling them to easily perform tests on unconventional materials and in unconventional locations. “I have no hesitation recommending the company,” Donald McNicol said of Copper Mountain Technologies. “The prices are reasonable, the product is great technically, and the customer support is good.”

Applications

Follow the link to learn more about the solutions CMT offers for various applications, as well as an opportunity to tell us about your unique VNA applications.

VNA Suggestions

Submit this form and tell us about your VNA needs so that we may continue to design forward-thinking instruments that expand your test and measurement capabilities.