Why is it Necessary to Calibrate a Vector Network Analyzer?

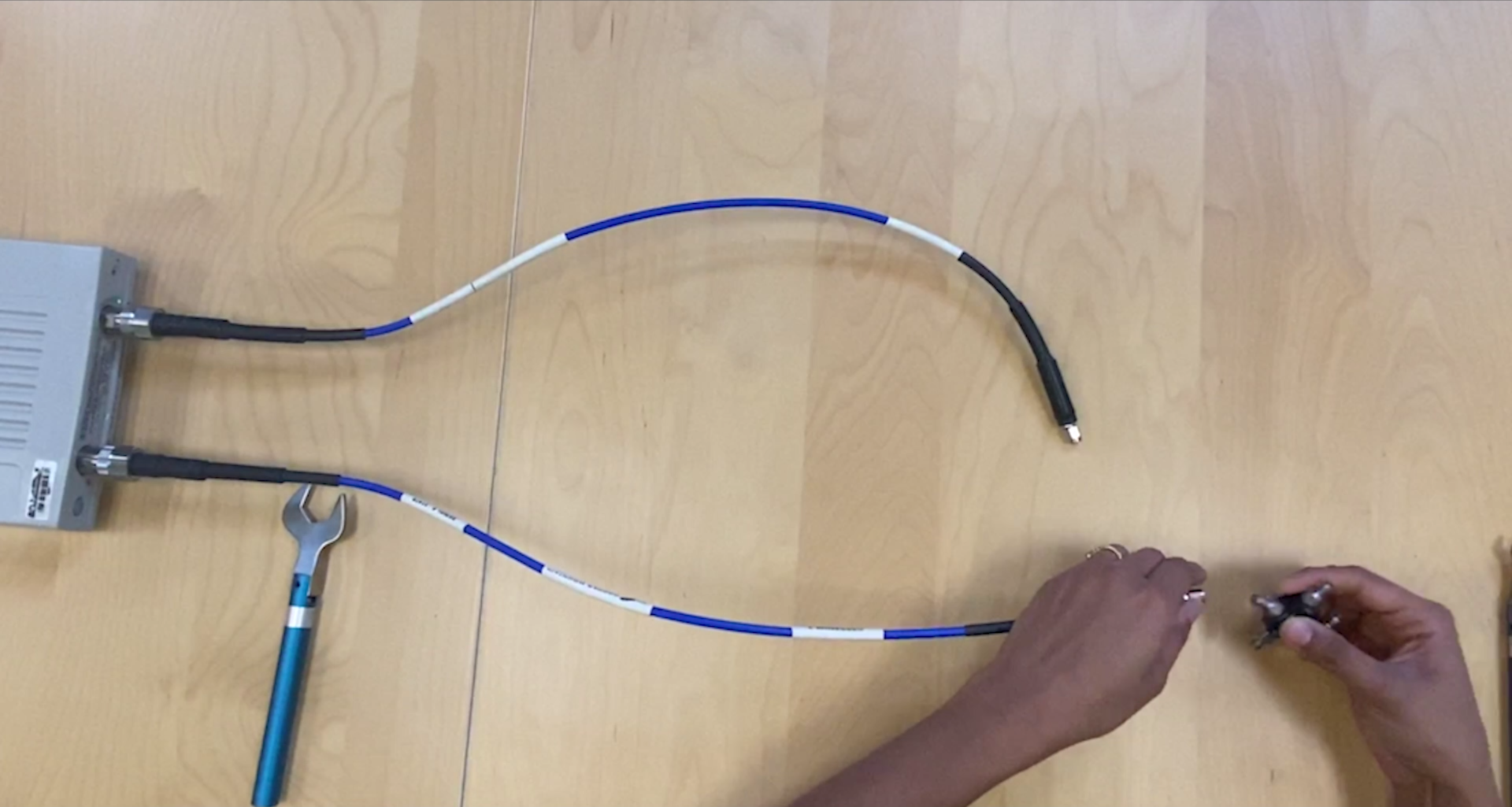

March 28, 2023Calibration corrects certain errors within the VNA and those added by connectors and test cables. If test cables are being used, establishing a reference plane is at the ends of the test cables is crucial, such that delay and phase measurements apply only to the Device Under Test (DUT) and not the DUT plus cables. All VNAs from Copper Mountain Technologies are factory calibrated to the output connectors of the equipment, so rough measurements can always be made without user calibration. It is sometimes helpful to attach the DUT to the VNA, then adjust the frequency range and number of points before performing calibration.

The diagram in Figure 1 shows the position of the calibration “planes” before and after SOLT calibration. With only factory calibration, the errors due to cables and connectors will not be corrected and there will be additional loss and phase shift. After SOLT calibration the calibration plane moves to the output of the test cables as shown.

Figure 1 – Calibration Planes

What Errors are Corrected?

The twelve-term error model is commonly used to describe the errors encountered in VNA measurement. Figure 2 and Figure 3 depict these errors in the forward and reverse direction.

Figure 2 – 12 Term Error Model, Forward

Figure 3 – 12 Term Error Model, Reverse

These two models are mirror images and apply when the VNA signal goes from Port 1 to Port 2 and from Port 2 to Port 1. It is sufficient to understand one to understand the other. The arrows in the diagram represent RF signals traveling left to right and right to left. a0 and b0 are both attached to Port 1 of the VNA but represent nodes for signals moving in each direction.

The DUT is in the middle, and it is the goal of calibration to be able to correct all the errors on either side in order to determine S11, S12, S21, and S22 of the DUT.

eoo is the directivity error. Within the VNA bridge, there is a leakage signal from the forward traveling wave into the reflection port. This looks just like a valid reflection to the VNA, and must be removed in order to see the actual reflection.

e10 and e01 are reflection tracking errors, usually combined, and represent the loss and phase shift experienced by a signal leaving the VNA and then being reflected back through the test cable and the bridge of the VNA before being measured by the internal receivers.

e11 is the source match error. Looking into the end of the Port 1 test cable, this is the difference between the actual source impedance and 50 ohms. Even if the output impedance of the VNA were a perfect 50 ohms, small variations in the characteristic impedance of the test cable can introduce an error.

e30 is the isolation error. This accounts for any signal which makes its way from Port 1 to Port 2 without passing through the DUT. This includes internal VNA leakage and parasitic input to output coupling of a test fixture or probe to probe coupling in a semiconductor test probe station. Internal VNA leakage is usually below thermal noise, and thus may often be ignored when using good fixturing.

e22 is the load match error. Looking into the end of the Port 2 cable, this is the difference between the actual load impedance and a perfect 50Ω load. Even if Port 2 of the VNA has a perfect load, small variations in the characteristic impedance of the test cable can introduce an error.

e32 is the transmission tracking error. This error represents the loss and phase shift experienced by a signal passing through the test cable and the bridge of the VNA before being measured by the internal receivers.

The network diagram is helpful to understand signal interaction. For instance, the Source Match error term e11 only affects signals reflected from the input of the DUT (s11) and signals reflected back from the DUT output which pass through it backwards (s12).

A full two-port calibration quantifies all twelve errors and mathematically removes them from the measurement. Other kinds of calibration such as one path 2-port or simple response calibration may only remove some of the errors. Error correction and residual errors are explored in more detail in [1].

What Happens if I Don’t Calibrate the VNA?

If the VNA isn’t calibrated before measurement, then the reference plane will be at the VNA connectors, and any phase or delay will include the excess delay and phase shift of the test cables. Additionally, there may be ripple in the transmission measurements (s12 and s21) due to error term constructive and destructive interference. Reflection measurements will also show measurement ripple due to interaction with the uncorrected directivity leakage and source match error.

Figure 4 – Response Thru vs Full 2-Port Calibration

Figure 4 above shows an s21 ripple in a filter measurement with full 2-port calibration in blue vs response thru calibration in brown. The response calibration does not correct source or load match errors. If you were to visualize the effect of a resistor voltage divider with slightly changing values, you would see how these ripples might occur. The source match is one resistor in front of the DUT, while the load match is the other resistor on the output of the DUT. This will cause ripples in low insertion loss measurements like a filter passband. The effect is not noticeable at higher attenuations, such as the stopband of the filter. See [7] for more information.

What Should I Use to Calibrate the VNA?

A good Short, Open, Load, and Thru (SOLT) calibration kit may be used to perform calibration on a VNA. Each of these calibration standards are measured during the calibration process, and the known characteristics of the standards vs actual measurements are used to calculate the error terms (see [3], [4] and [6]).

Alternatively, you can use an automatic calibration module. This device has internal calibration standards which are automatically switched into place. The result is a simpler and much more accurate calibration (see [2] and [5]).

References:

- Copper Mountain Technologies, “Introduction to the Metrology of VNA Measurement”, https://coppermountaintech.com/introduction-to-the-metrology-of-vna-measurement/

- Copper Mountain Technologies, ”What is an Automatic Calibration Module?”, https://coppermountaintech.com/what-is-an-automatic-calibration-module/

- Copper Mountain Technologies, ”Calibration Types and Considerations”, https://coppermountaintech.com/calibration-types-and-considerations/

- Copper Mountain Technologies, ”Conducting Calibration with the SOLR (Unknown Thru) Method”, https://coppermountaintech.com/conducting-calibration-with-the-solr-unknown-thru-method/

- Copper Mountain Technologies (video), ”How Do I Use an Automatic Calibration Module (ACM) to Calibrate My VNA?”, https://coppermountaintech.com/video/how-do-i-use-an-automatic-calibration-module-acm-to-calibrate-my-vna/

- Copper Mountain Technologies (webinar), “Lizard Lessons – Calibration Types On-Demand Webinar Recording”, https://coppermountaintech.com/webinar-calibration-types-for-vector-network-analysis-form-page/

- Copper Mountain Technologies (webinar), “VNA 101 Bootcamp – Importance of Calibration Webinar”, https://coppermountaintech.com/webinar-vna-101-bootcamp-importance-of-calibration-form-page/

- Copper Mountain Technologies (webinar), “VNA 101 Bootcamp – Advanced Calibration Techniques”, https://coppermountaintech.com/vna-101-bootcamp-webinar-recording-sign-up-advanced-calibration-techniques/