The Importance of Equipment Grounding

May 25, 2023The Importance of Equipment Grounding

Proper equipment grounding is important for both the safety of the user and for the protection of the equipment. High voltage static charges can build up on the human body and on dielectric objects in the lab area. Dangerous AC mains ground loops may exist on electrical or electronic equipment. Mitigation of these issues requires different grounding strategies.

How is Electrostatic Discharge (ESD) Handled?

ESD in a test station environment should be addressed in several ways outlined in this section. Static charge builds up easily on dielectric objects with low conductivity, such as the plastic cart in Figure 1.

Figure 1 – Plastic Utility Cart

Simply rolling this cart on certain surfaces might be sufficient to build a large static charge. If carts are necessary for your setup, ensure that they are ESD safe using a method to drain charge into the floor, such as the discharge chain in Figure 2. People can also bring a significant charge into the test area. ESD heel straps will drain the charge from operators, as long as the floor has been treated with an ESD mitigation coating and the test area itself has ESD mats in front of the benches.

Never allow Styrofoam or large plastic objects in the test area, as they can hold a very large reservoir of electrostatic charge.

Figure 2 – Discharge Chain

The benchtop should be covered with an ESD mat connected to station ground through a 1 megohm resistance. The operator should wear an ESD wrist-strap attached to the mat, since they will likely be seated, and heel-straps ineffective.

Figure 3 – ESD Mat and Wrist Strap

All ESD grounds are to be attached to the station ground through a high impedance, such as a 1 megohm resistance. The high resistance is sufficient to draw down static charge in a way that does not create a spark or current surge.

How is Equipment Grounded?

Test equipment and other electrical items on the test bench should have a direct connection to the station earth ground. This ensures that hazardous voltages from the AC mains do not develop on metal surfaces. Note that an ESD discharge could be drawn from the operator as a consequence of this grounding, which is why wrist and heel straps are so important.

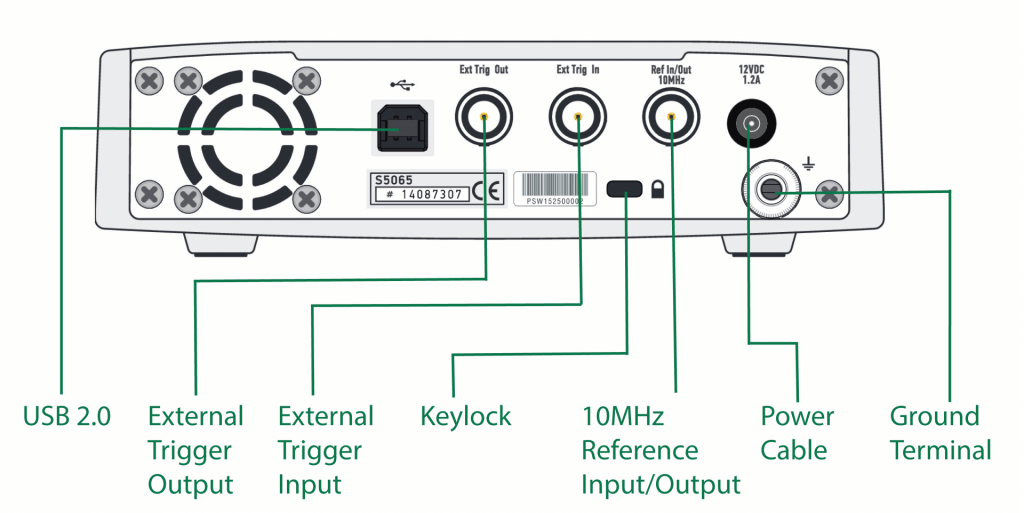

Figure 4 shows the rear panel of a typical compact VNA from Copper Mountain Technologies. The ground terminal is clearly indicated in the lower right corner and should be directly connected to the station earth ground.

Figure 4 – Rear Panel of VNA Showing Ground Terminal Connection

Summary

Grounding is essential when working with any test equipment. The grounding protocols outlined in this document can be summed up as follows:

- Ground the chassis of all equipment to the test station earth ground.

- Do not bring charge into the test area via carts or people.

- Do not allow large dielectric materials in the test area as they are reservoirs for charge.

- Utilize heel straps and wrist straps on test personnel.

- Use ESD floor mats and benchtop mats at the test station.

- Maintain humidity in the test area at 30% or more.