Using a Databased SOLT Calibration Kit

April 19, 2018Introduction

Copper Mountain Technologies produces lab-grade VNAs with outstanding measurement accuracy. As with every VNA, performing a good calibration is necessary for maximizing the accuracy of VNA measurement results, for de-embedding the effects of imperfect cables and components in the fixture, and for moving the reference plane to the DUT interfaces. There are several approaches for determination and application of VNA measurement corrections, including port extension (a relatively crude, approximate method), fixture de-embedding (with accuracy depending on correctness of the model), and calibrating with a calibration kit (a high accuracy approach).

Generally, there are two broad categories of calibration kit types: traditional mechanical kits and automatic/electronic calibration modules. Within mechanical kits, there are two types of kits: those with standard “polynomial” coefficients and those with full S-parameter characterization data, also known as databased kits.

This application note introduces databased calibration kits, explains why their use is growing in popularity, and describes how they can be used with Copper Mountain Technologies VNAs.

What is a Databased Calibration Kit?

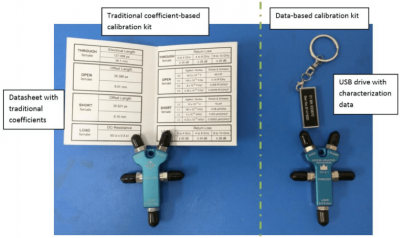

Unlike coefficient-based mechanical kits, all of which are normally supplied with the same set of coefficients, a databased calibration kit includes a measured result of each individual standard in each kit produced. The goal when manufacturing a traditional calibration kit is trying to be as close to a mechanical and electrical specification as possible during fabrication and relies on this consistency to achieve a good accuracy with a standard set of coefficients.

In contrast, each standard in a databased calibration kit is very precisely characterized after fabrication; the measured data is supplied with the kit and, when subsequently used in the VNA for calibration, provides outstanding measurement accuracy. The advantage of databased calibration kits is such kits can achieve a similar or superior accuracy compared with traditional kits, at a lower cost to manufacture. Databased kits are starting to become more popular in recent years, as users have begun to recognize the high quality of measurement they can provide, at a relatively low cost.

Both types of calibration kit are supported by modern VNAs, thanks to significant increases in the memory and computational resources available to instruments. All Copper Mountain Technologies VNAs support databased calibration kits.

In a databased calibration kit, you will find the characterization data for each standard, which is normally supplied as touchstone, probably on a USB thumb drive. The data corresponds to that particular serial number of calibration kit. Vendors supplying databased kits now include Keysight, Rosenberger, and Spinner among others.

Here is a picture comparing a traditional, coefficient-based calibration kit with a databased calibration kit:

Tables of data corresponding to a traditional kit and databased kit are shown below:

Defining a Databased Kit in VNA Software

Since every databased calibration kit has a unique set of data (usually contained in a Touchstone S1P file), the calibration kit definition needs to be created for each kit. This application note is based on the software of the Copper Mountain Technologies’ Full-Size 804/1, a 2-port VNA measuring from 100 kHz to 8.0 GHz; other instruments’ software will follow a similar procedure as well.

To create the databased calibration kit definition, use the softkeys along the right side of the user interface to navigate to Calibration -> Cal Kit. Choose any empty calibration kit entry and type in a Label name. Now, choose “Define STDs”. When defining the standards, standards with database— such as Short, Open and Load in this example—should be specified as databased.

Figure 1: Choose any blank calibration kit in the table, and type the kit Name and Description.

Figure 2: Create all the individual standards. Each databased standard should be specified as Type “Data-Based”.

Next, use the softkey sequence Define STD Data > Load Data From Touchstone File. Navigate to and load the Touchstone file corresponding to each standard.

Figure 3: Loading the touchstone file supplied with the kit for each standard.

After successfully defining the standards, you also need to specify the class of each before performing the calibration. Go to Calibration > Cal Kit and select the databased kit. Then choose Specify CLS; select ports and subclasses for each standard. Enabling “Assign Same STDs To All Ports” can reduce the number of entries required when the same standards are used on all ports.

Figure 4: Specifying Classes and port scope of each standard.

Performing Calibration with a Databased Kit

Now that the kit is defined, you are ready to perform the calibration as usual. Just select the calibration kit by using the menu sequence Calibration > Cal Kit > Select. Now perform the calibration of your choice via the sequence Calibration > Calibrate.

Figure 5: Selection of the calibration kit.

Conclusion

Databased calibration kits are another option for mechanical calibration kits. It’s likely to be a more cost-effective solution providing similar or better accuracy of measurements compared with precision coefficient-based kits. Defining and using a databased calibration in CMT VNA software is fairly easy and straightforward. As always, if we can be of any help in your calibration or measurement solution, feel free to contact our support team at support@coppermountaintech.com.