Materials Measurement

Compass Technology Group (CTG) is focused on taking innovative materials measurement research to product. CTG integrates Copper Mountain Technologies’ network analyzers into their systems with probes. Their systems include conventional and advanced measurements, such as free space, resonant cavity, and waveguides.

Compass Technology Group (CTG) is focused on taking innovative materials measurement research to product. CTG integrates Copper Mountain Technologies’ network analyzers into their systems with probes. Their systems include conventional and advanced measurements, such as free space, resonant cavity, and waveguides.

CTG can also assist with non-destructive, real time testing of food and beverage quality parameters, such as moisture and sugar levels in crops, liquid level in bottled beverages, and woody chicken breasts. Systems containing purpose-built antennas and microwave analyzers direct radio signal at materials under test and measure transmission and reflection parameters. Those results are translated into information about important quality parameters in food and beverage testing.

AMMP Spot Probes

Compass Technology Group develops and utilizes specialized probes that enable the measurement of materials in a number of unique environments. CTG’s recently developed spot probe technology called Advanced Microwave Mapping Probes (AMMP) is a significant improvement over traditional dielectrically loaded horns due to optimized metal radiating elements, dielectric loading, and shape. The spot probes are specially designed antennas encapsulated in a dielectric and optimized to provide a small illumination spot 3 to 8 cm in front of the probe.

This Comparison of Materials Measurement Accuracy of RF Spot Probes to a Lens-Based Focused Beam System weighs the performance of CTG’s AMMP Spot Probes against the well-established free-space focused beam technique for microwave characterization of materials.

Take an in-depth look at the AMMP Spot Probes available from CTG.

Custom AMMP Measurement Systems Featuring CMT VNAs

Compass Technology Group has developed several custom measurement solutions that feature their AMMP Spot Probes in combination with a CMT VNA to tackle complex measurements.

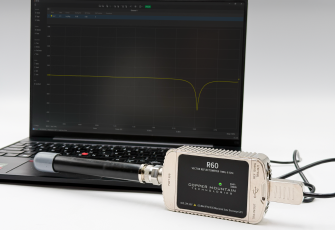

Handheld System

This portable, handheld reflectometer system is suitable for point inspection of RF coatings and materials. This system provides 2-18 GHz surface reflectivity measurement using CTG’s RF spot probe technology. This system integrates with a 1-port VNA from CMT, eliminating the RF cable and enabling faster, more reliable measurements.

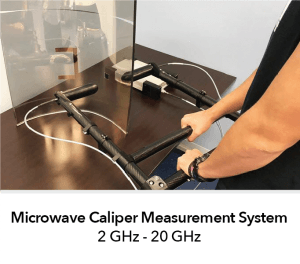

Microwave Calipers Measurement System

This lightweight and adjustable fixture secures wideband 2-20 GHz probes at the proper alignment and distance for optimal measurements. It is versatile and easy to use with multiple specimen types and sizes. The RF spot probes can even be removed and used as hand-held measurement devices on specimens that are too large to fit in the largest setting. This system extends the application capabilities from the lab where a tabletop setup is likely the best option, to include the production setting where the user may want QA measurement capabilities for oddly shaped, sized, and positioned DUTs.

Advanced Radome Diagnostic System (ARDS)

This measurement system uses a microwave sensor to measure the electrical properties of a radome to assess its health and performance.

Copper Mountain Technologies' VNAs incorporated into Compass Technology Group's Materials Measurement Solutions:

Other Compass Technology Group Materials Measurement Solutions: