Special Considerations when Using CMT VNAs

in High Speed Semiconductor Characterization Applications

Copper Mountain Technologies’ Cobalt VNAs have the same lab-grade performance as other CMT VNAs, but opens up the IF bandwidth for greater dynamic range. Cobalt VNAs are ideal for high speed measurements, especially high volume semiconductor testing applications. The Integration of a VNA into such a system has some unique considerations and issues. Keep reading below to learn more.

For high volume testing environments Copper Mountain Technologies’ Cobalt instruments are designed with this rather extreme requirement in mind. Our Cobalt VNA family allows for really exceptionally high sweep speeds at the further trade-off of dynamic range. A wider IF bandwidth, along with other big improvements especially to the data processing components of the instrument, are what enables Cobalt VNAs to operate at such great measurement speeds.

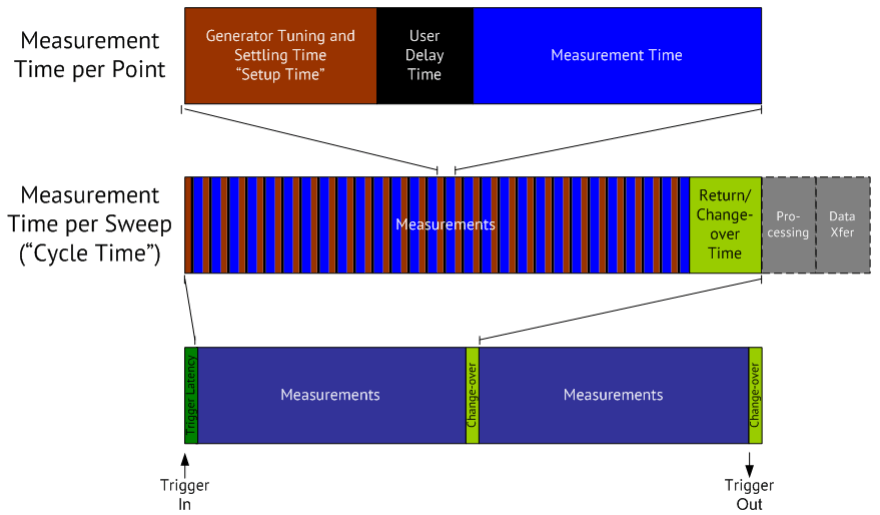

In the case of a semiconductor test scenario, you should consider the entire measurement cycle and suppose it is initiated by a trigger event, most probably an External or Bus trigger. There will be a small latency between the trigger and the initiation of the measurement, which we refer to as Trigger Latency in the figure to the left. We also have indicated the point at which the output trigger event occurs, as soon as the measurements are complete. This trigger output is another new feature of the Cobalt series, which is particularly useful when the VNA is integrated into a larger test system.

When integrating into test systems, you should consider the external interfaces available for that. The Cobalt VNAs have both external trigger inputs and outputs, as well as reference frequency input and output connections.

In the context of a semiconductor testing integration scenario, the external trigger output really is quite important because it is very often used to tell the handler to advance to the next position and begin testing. The port can be configured for several different modes of operation, including to generate an output trigger before setup of the measurement, before sampling begins, after sampling completes, when the instrument is ready for a next trigger, when the sweep ends, or when the measurement completes. In addition, the polarity of the output trigger can be configure for a positive or negative-going pulse. The wide range of configurations for the trigger output make integration of the Cobalt VNA very straightforward.

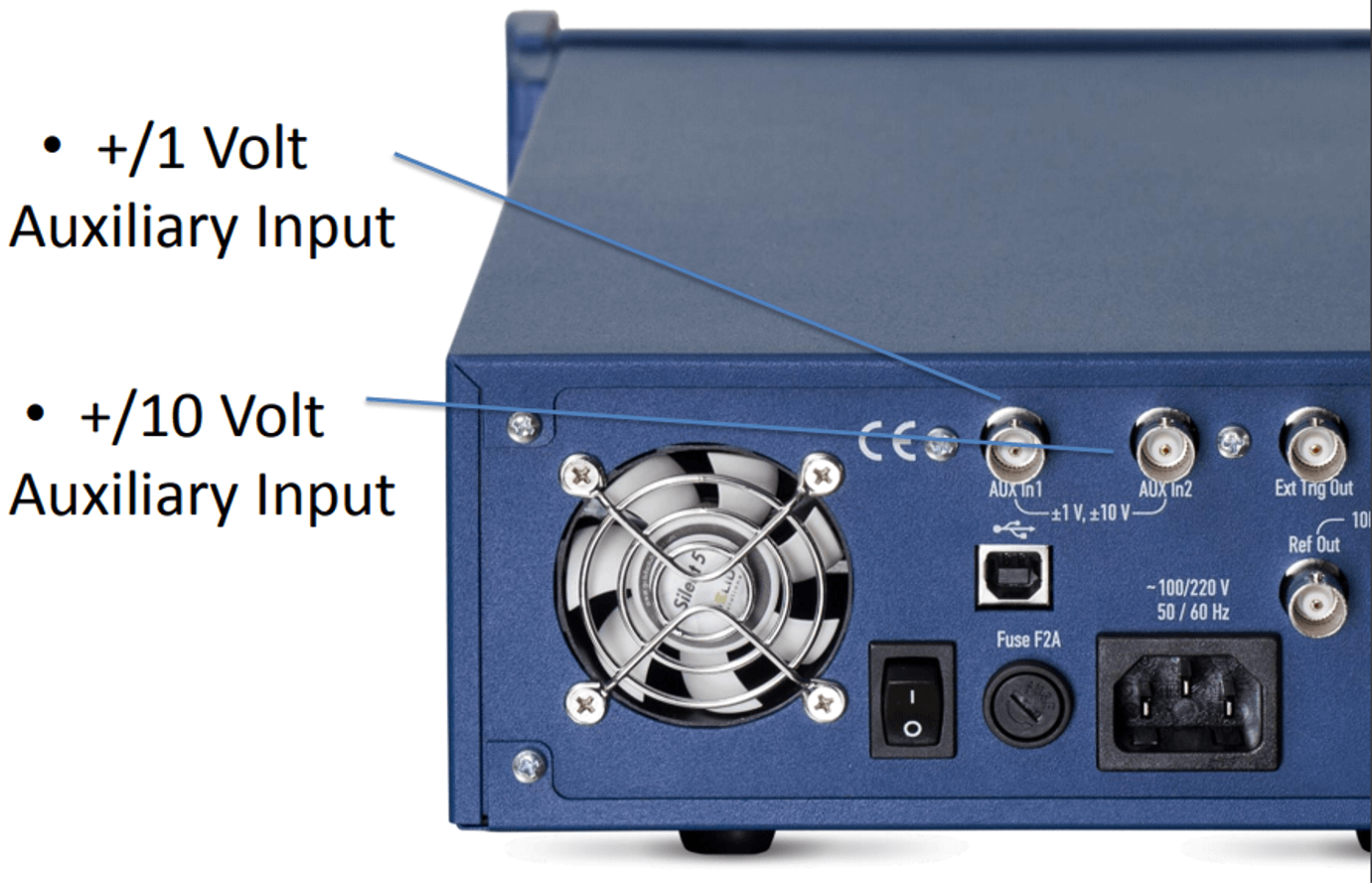

Another helpful feature of the CMT Cobalt VNAs, in the context of semiconductor testing applications, is the auxiliary input ports. There are two auxiliary inputs, one covering a +/- 1 Volt measurement range and the other covering +/- 10 Volts. These can be used to sample a system or DUT voltage or current, such as might be required when testing an amplifier chip’s efficiency or a log detector’s output voltage, for example. The inputs can also be used to monitor temperatures or other system parameters as desired. The Aux input data is collected synchronously with the S-parameters, which can provide some convenience advantage compared with using an external DMM.

Besides the hardware, the other major consideration when integrating a VNA into any larger test and measurement system, including semiconductor device characterization, is the ease (or lack thereof) with which measurements can be automated and performance data retrieved and stored. Just like all CMT VNAs, the Cobalt instruments are USB-driven and PC-controlled. The automation interface typically exists between your programming environment and the VNA application within the same PC, which is quite a nice simplification and also speeds up measurement transfer compared with legacy protocols like GPIB or even Ethernet. It’s quite straightfoward to port your legacy code to the CMT COM interface, which as you can from the subset of commands shown here, closely resembles syntax-wise the traditional SCPI and VXI commands we’re all accustomed to. We also offer programming examples and guides for many environments including VEE, C++, VBA, VB.NET, MATLAB, Octave, C#, and Python, and we also have a LabVIEW driver which you can access on our website.

- De-embedding and Advanced Calibrations

Semiconductor testing is also demanding in a few other ways compared with ordinary bench top testing. Specifically on-wafer probing requires some advanced calibration capabilities including de-embedding, which of course all our instruments support in the base software.

- Measurement System Size and Weight

- Reliability

CMT analyzers are exceptionally robust because they contain few of the parts that tend to fail or be damaged on traditional instruments: screens, hard drives, buttons, operating systems; these are the failure points of conventional designs.

- Modularity and Obsolescence Risk

You can replace your PC when it is obsolete without gutting the instrument or overpaying.