Reshoring Success: How Copper Mountain Technologies used Indiana Manufacturers to Transform its Production

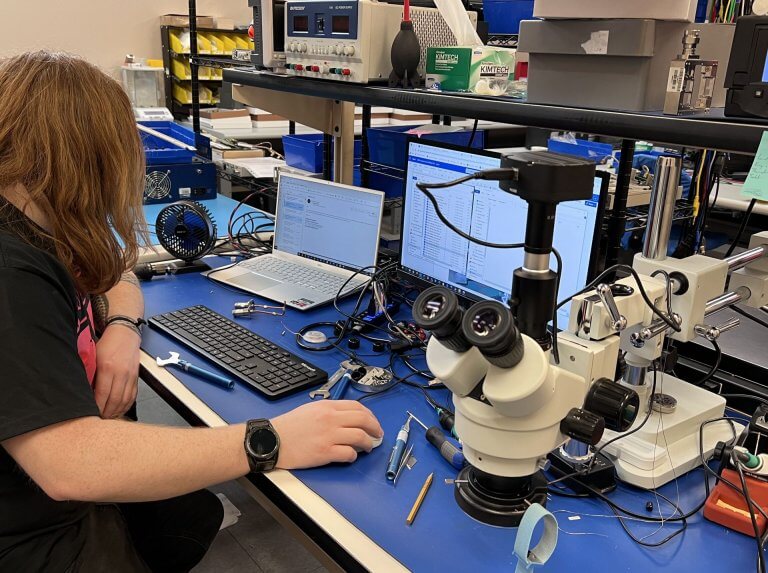

In the wake of the Covid pandemic and broader global instability, many organizations have been forced to take stock of their business processes. For Copper Mountain Technologies, it was clear there was a need to overhaul existing production and manufacturing processes to solve issues of component procurement and produce enough inventory to match customer demand. With the help of organizations like Conexus, and the existence of quality manufacturing companies local to their Indianapolis headquarters, CMT was able to efficiently onshore its VNA production and assembly to the US, while supporting other local small businesses. This allowed the company to streamline its manufacturing process and empower its engineers and technicians to meet customers’ needs by more efficiently producing vector network analyzers and custom S-parameter measurement modules.

In 2023, CMT was awarded a Manufacturing Readiness Grant by the Indiana Economic Development Corporation (IEDC). This grant, administered by Conexus Indiana, is available to Indiana manufacturers committed to enhancing their operations and accelerating Indiana’s manufacturing and logistics industry. CMT is also participating in the IEDC’s Economic Development for a Growing Economy Program (EDGE), which enabled the company to receive a tax credit based on the expected creation of 16 new full-time positions for Indiana employees by 2026. The EDGE program provided CMT with additional flexibility as they brought on new staff to accommodate their increased production workload. “We are thankful to the IEDC and Conexus for aiding us in our efforts to continue our growth within the manufacturing industry here in Indiana,” said Irena Goloschokin, CEO of Copper Mountain Technologies. The manufacturing readiness grant and EDGE program were key catalysts to CMT’s onshoring success and helped bolster production capabilities at their Indianapolis headquarters office.

Even with the boost provided by the Manufacturing Readiness Grant, CMT would not have been able to successfully transition its production operations to Indianapolis without access to talented local manufacturing partners. Divsys, a branch of ICAPE Group, takes care of PCB fabrication and assembly and is located just 20 minutes away from CMT’s Indianapolis headquarters. Stephen Gould in Whitestown, IN provides high-quality packaging that protects the sensitive measurement instruments while enhancing aesthetic appeal. They support CMT’s constantly evolving design by rapidly producing new designs and samples that enable a trial-and-error approach to product packaging.

CMT uses Indianapolis-based Estes Design and Manufacturing for sheet metal fabrication for the VNA housings. CMT’s willingness to explore changes in existing designs to optimize the manufacturing process allowed the companies to work through the prototype phase in tandem before beginning full-scale production which enabled the entire process to flow seamlessly through completion. Some additional local manufacturers utilized by CMT are LaserScribe in Indianapolis, who provide laser engraving services, and Eagle Magnetic Company, Inc. in Crawfordsville, IN which provides powder coating services.

These great manufacturing partners have allowed CMT to take more control over every aspect of their production process, resulting in lower lead times. The flexibility of these various partnerships has created a more agile manufacturing process which is ideal for some of the custom solutions the company provides to users with unique measurement applications in industries like agriculture, defense, materials measurement, and more. Working with local manufacturers offers a unique personal touch, including the convenience of having crucial components delivered by hand. In-person discussions are also easier to arrange, fostering stronger relationships and enabling more impactful, hands-on collaboration than virtual meetings. Copper Mountain Technologies’ decision to overhaul its manufacturing operations has significantly enhanced its production capabilities, reduced lead times, and increased inventory efficiency. This transition wouldn’t have been possible without the exceptional support of local manufacturing partners and organizations like Conexus. By prioritizing collaboration within the Indiana community, CMT is not only meeting its customers’ needs but also driving economic growth and innovation in the region. This success underscores the value of investing in local manufacturing ecosystems and the power of partnerships in shaping a resilient and sustainable future.