TRL Calibration Kit Design & Fabrication

April 19, 2018Introduction

Copper Mountain Technologies provides metrologically sound, lab grade USB VNAs which support advanced calibration techniques, including TRL calibration. True TRL calibration requires a VNA with 2 dedicated measurement receivers per test port; except for the TR series, all 2+ ports CMT instruments have all the necessary receivers and internal architecture required for true TRL calibration. This application note introduces TRL calibration and describes how to configure TRL kit and perform a TRL calibration in the CMT software.

TRL Calibration Defined

TRL calibration is a 2+ port calibration which consists of three standards, Thru (T), reflect (R), and line (L). It has some variants such as TRM, LRL, LRM, but the principles behind them all are the same.

- Thru: Connects two transmission lines directly. Everything here will be embedded by the calibration, unless an offset by the calibration, unless an offset is specified in the kit definition.

- Reflect: Can be either an open or a short to provide a 180-degree phase shift.

- Line: The line length is the difference between this standard and the Thru, shown as l/4 in the diagram. The line length must correspond to between 0° and 180° for the calibration frequency range. It’s normally chosen to be between 20° and 160°, with headroom.

The picture shown above assumes the DUT is perfectly in the middle of the Thru standard. After calibration, the reference plane will be moved from the VNA ports to the two ends of DUT, shown by dashed lines in the picture.

If the DUT is not in the middle of the standards, offset delays will need to be specified in the TRL calibration kit definition file to move the reference plane.

Without going into detail about the math behind TRL calibration, the method uses TRL standards to determine the ABCD parameters for systematic errors, also known as the “error box”. There will be an error box on each end of the DUT, which is then de-embedded from the measurement result to find the ABCD parameters for the DUT. The measured ABCD parameters are transformed to S-parameters, yielding the response of the DUT, our ultimate goal. Readers interested in more detail about the theoretical basis for TRL calibration can find many documents online.

Why TRL?

Unlike SOLT calibration, which relies on perfectly-defined reference standards, TRL calibration is mathematically perfect without any characterization of the standards at all. So it can be extremely accurate if all the standards are well-built, and you don’t need to worry about the connector since DUT is likely to be soldered on the board. Therefore, TRL is a good fit for applications such as on-wafer measurements with probes.

However a main disadvantage of TRL calibration is that the accuracy of calibration and subsequent measurements is highly dependent on the quality and repeatability of the TRL standards. At lower frequencies, this is not a significant problem, but at higher and higher frequencies, you need to consider factors such as fringe effects of your reflect standards, physical bending of the board, and other nonidealities.

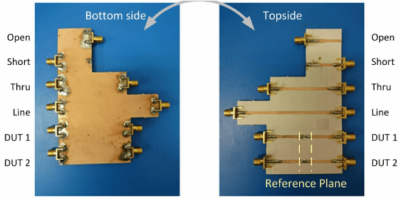

Fabrication of a TRL pattern

When fabricating a TRL board, each standard needs to have high enough accuracy to fit your application. The frequency range of the application needs to be decided first, before designing the, pattern since it will dictate both trace width and line length. The impedance of each standard on the board needs to be the same, which is normally the system impedance (50 ohm) at the center frequency.

When designing the Thru standard, you can simply connect two transmission lines together and ignore the DUT size to make a Thru. It’s the simplest of the standards.

The Reflect standard design can make use of either an open or a short to achieve a 180 degree phase shift. Sometimes, a short will be a better standard at higher frequency, since the fringe effects of the open will be noticeable at high frequency.

When it comes to the Line standard, you need to calculate the effective permittivity instead of the material’s nominal permittivity to get the correct line length. Mathematically, the line length must be between 0 and 180-degrees for your frequency range, so that the sign of the transmission parameter will not change. To leave some headroom, people usually choose a line length corresponding to no less than 20 degrees at their lowest frequency and 160-degrees at their highest frequency, which will provide a frequency span factor of 8:1. If your frequency range exceeds this limit with a single line, you can design multiple lines to cover a wider range as well1.

1 With modern VNAs, thanks to reductions in jitter time compared with older analyzers, the minimum frequency requirement is not as strict and the TRL standards can be safely used somewhat below the frequency corresponding to 20 degrees.

If you are trying to fabricate a TRL calibration kit for high frequency, such as higher than 6 GHz, there are some approaches you can take to get the best performance. Firstly, you can use a short standard instead of an open for the reflection, to reduce fringing effects.

Secondly, you can surround your standard with PCB vias, to help constrain the electrical field in order to get a more accurate standard. Using laminate on both sides of the PCB, instead of just one, will also help better constrain the electrical field.

Defining a TRL kit in the VNA software

To define a new calibration kit in CMT software, go to Calibration > Cal Kit, choose a blank Cal Kit, and type a name for its Label. Next, choose “Define STDs”.

Figure 1: Choosing and naming a blank calibration kit

Figure 2 – Define Standards

If your DUT is not in the middle of the thru, you will need to add offset delay to your standard definition. The loss and/or coefficient is recommended be entered as well to improve accuracy. Otherwise, since TRL calibration does not rely on precise definition of the standards, the only parameters required are the Fmin and Fmax for each standard, especially the Line.

The last step is to specify classes. With the newly created kit selected, go to “Specify CLSs” and assign each standard to the appropriate port and standard type, as shown.

Figure 3 – Assign Standards

After defining the calibration kit, performing the calibration will just follow the normal procedure. Select your TRL calibration kit using the menu sequence Calibration Þ Cal Kit, choose your kit and then Select. Then start the calibration from Calibration Þ Calibrate Þ 2-Port TRL Cal. Turn on Multiline if you wish to use more than one line.

Example TRL calibration

This calibration kit was designed for use between 422 MHz and 3.37 GHz. Therefore, the center frequency is √422 × 3370 = 1193 MHz. An online microstrip line calculator was used to calculate the effective permittivity and line width of the 50 ohm trace at 1193 MHz. Using a quarter wavelength at 1193 MHz will be a good start for choosing a line length. You can perform calculation based on that to get each line length that goes from 20 to 160 degree when the frequency ranges between 422 MHz and 3.37 GHz. If you want to double check with your calculation, the line length is 27.264mm. The laminate being used is Roger 4725JXR with thickness of 0.77mm, dielectric constant of 2.55 and copper of 35um thick.

Here is the measurement result after calibration. The results are purely illustrative; you can easily obtain a better result by making use of better soldering and fabrication processes. The following measurement is done with Planar 804 from 422 MHz to 3.37 GHz. The Thru standard is used as the normalization reference, so the thru measurement only shows us the repeatability of the calibration kit. Port 1 and port 2’s reflection coefficients, S11, when connected to open standard is shown below. Ideally, it should always be 0dB. And the variation here is less that ±0.1dB.

The DUT here is a 100Ω surface mount resistor, so the ideal result is -6.02dB for transmission and reflection:

The DUT here is 4.7 pf SMT capacitor. The ideal result is generated by simulation of an ideal 4.7 pf capacitor.

Conclusion

TRL calibration is a mathematically perfect calibration approach, suitable for 2+ port analyzers, with the advantages including accuracy and flexibility. The difficulty with fabricating and using a TRL kit lies with manufacturability and repeatability. We hope this application’s discussion about TRL calibration, considerations when designing and producing a TRL kit, and application of the TRL kit have been useful.

If we can be of assistance by further explaining any aspect of TRL calibration, please don’t hesitate to contact us as support@coppermountaintech.com.