Cleaning off any contamination on the connector mating plane surfaces and threads can extend the lifetime of the connector and improve the quality of calibration and measurement.

Remove loose particles from threads and mating surfaces of the connectors with low-pressure air or nitrogen. Using a compressor is not recommended (air filtration is required), it is safer to use a can. Compressed air is the safest method for cleaning connectors with air dielectrics. Wear safety glasses when cleaning.

If further cleaning is required, a lint-free cleaning swab can be moistened with isopropyl alcohol and applied lightly. If desired, you may clean the connector with a dry cleaning swab without alcohol first. If contamination is still present, use alcohol. Use minimum amount of alcohol.

Only clean connectors with alcohol when there is no power cord connected, ensuring that the instrument is in a well-ventilated area. Allow all residual alcohol moisture to evaporate, and the fumes to dissipate prior to powering up the instrument.

If the connector is still contaminated, use a very small toothpick with a small amount of alcohol applied. Use a magnifying glass when using a toothpick to clean, and apply extreme care to avoid damaging the connector.

CAUTION |

Never use any metal objects or any abrasives to clean the connectors. Never use high pressure air (>60 psi). Never allow alcohol into connector support beads. If alcohol unintentionally enters connector support beads, allow the connector to dry for at least 8 hours. |

Avoid using too much pressure on the center conductor, as swab fibers can become tangled in the center of the female conductor. When the alcohol evaporates, use compressed air to ensure that the surface is clean.

CAUTION |

Never apply lateral force to the center conductor. Never wipe the center conductors of the female connectors. They should be cleaned with compressed air. |

Connector cleaning should be performed as follows:

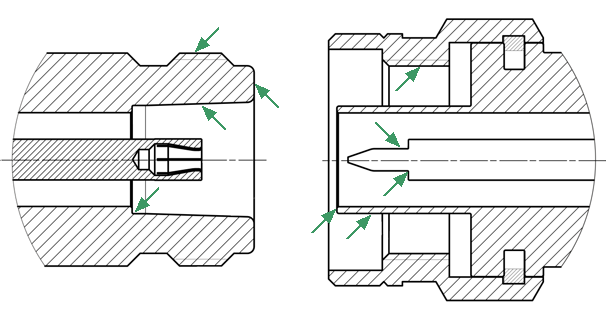

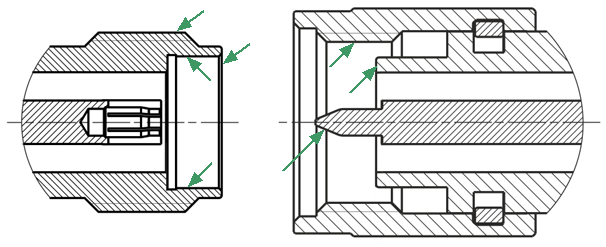

1. Wipe the connector surfaces with the swab moistened with alcohol as shown by arrows (See figures below).

2. Use compressed air to clean the other internal connector surfaces.

3. Let the alcohol evaporate.

4. Visually inspect the connectors to make sure that no particles or residue remain.

5. Repeat the cleaning procedure if necessary.

6. If cleaning does not correct any issues, the connector should not be used for measurements.

When cleaning connectors:

•Always use protective eyewear when using compressed air or nitrogen.

•Keep isopropyl alcohol away from heat, sparks, and flame. Use with adequate ventilation. Avoid contact with eyes, skin, and clothing.

•Avoid electrostatic discharge (ESD). Wear a grounding wrist strap (with a 1 MOhm series resistor) when cleaning connectors.

|

Type-N Connectors (female and male) |

|

3.5 mm NMD Connectors (female and male) |

Procedure for Cleaning Connectors |