A one-path two-port calibration combines full one-port calibration with transmission normalization. This method allows for a more accurate estimation of transmission tracking error (Et) than using transmission normalization.

One-path two-port calibration involves connection of the three standards to the source port of the Analyzer (as for one-port calibration) and a THRU standard connection between the calibrated source port and the other receiver port (See figure below).

One-path two-port calibration allows for correction of Ed, Es, and Er error terms of the source port and a transmission tracking error term (Et). This method does not derive source match error term (El) of a two-port error model.

An optional isolation calibration can be performed by measurement of two LOAD standards connected to both test ports of the Analyzer. In this case, the isolation error (Ex) is additionally corrected in the one-path two-port calibration.

note |

For isolation calibration, set a narrow IF bandwidth and firmly attach the cables. |

One-path two-port calibration is used for measurements of the parameters of a non-reciprocal DUT such as amplifiers in one direction, e.g. S11 and S21.

One-path two-port calibration

Before starting calibration perform, select an active channel, set the parameters of the channel (frequency range, IF bandwidth, etc), and select the calibration kit.

|

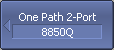

To open one-path two-port calibration submenu, use the following softkeys: Calibration > Calibrate > One Path 2-Port Cal |

|

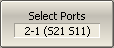

Select the direction of the calibration using the Select Ports softkey. The label on the softkey indicates the following: source port —> receiver port (measured parameters). |

|

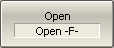

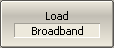

Connect SHORT, OPEN and LOAD standards to the source port in any consequence, as shown in the above figure. Perform measurements clicking the softkey Perform measurements clicking the softkey Open, Short, Load corresponding to the connected standard. The instrument status bar will indicate Calibration in progress... when the measurement is in progress. On completion of the measurement, a check mark will appear in the left part of the softkey. |

|

Connect a THRU standard between the test ports. If the port connectors allow through connection connect them directly (zero electrical length thru). Perform measurement using the Thru softkey. The instrument status bar will indicate Calibration in progress... when the measurement is in progress. On completion of the measurement, a check mark will appear in the left part of the softkey. |

|

To perform the optional isolation calibration, connect two LOAD standards to the test ports as shown in the above figure and enable measurement using the Isolation (Optional) softkey. The instrument status bar will indicate Calibration in progress... when the measurement is in progress. On completion of the measurement, a check mark will appear in the left part of the softkey. |

|

To complete the calibration procedure, click Apply softkey. This will activate the process of calibration coefficient table calculation and saving it into the memory. The error correction function will also be automatically enabled. |

|

To clear the measurement results of the standard, click Cancel softkey. This softkey does not cancel the current calibration. To disable the current calibration, turn off the error correction function (See Error Correction Disabling). |

|

|

note |

The calibration status can be checked in channel status bar (See General error correction status table) or in trace status field (See Trace error correction status table). |