When operating the Analyzer, it is often necessary to connect various devices to each other: cables to analyzer measurement ports, junctions to cables, calibration tools to junctions or analyzer ports, devices under test to ports, etc.

Connecting

Connect devices with coaxial connectors in the following sequence to ensure maximum repeatability of measurement results, as well as to prevent breakage:

1. Carefully align the connectors of the devices being connected.

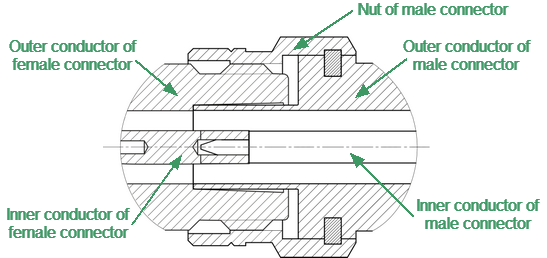

2. While holding the device that is being connected, tighten the male connector nut manually. The mating plane surfaces of the center conductors and the outer conductors must make uniform light contact, as shown in figure below.

|

Type-N connectors (female on the left, and male on the right) |

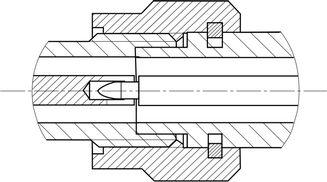

|

3.5 mm NMD connectors (female on the left, and male on the right) |

Connecting example |

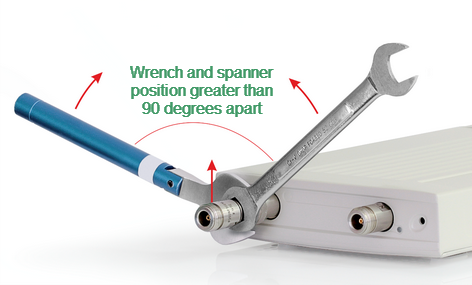

3. Tighten the male connector nut using the appropriate torque wrench while holding the device being connected, or hold the device by using an open-end spanner to keep it from rotating. Position the wrench and spanner within 90 degrees of each other before applying force. Finally, tighten the male connector nut by holding the wrench at the end of the handle. Tighten the connection just to the torque wrench “break” point (See figures below).

Hold the torque wrench by the end of the handle when tightening. The torque value depends on the connector type (See table below).

|

Correct torque wrench and spanner positions |

CAUTION |

The wrench and spanner should not be positioned more than 90 degrees apart. A larger degree of separation can cause excessive misalignment of the connectors.

Incorrect usage of torque wrench and spanner (too much lift on connection). |

Recommended Torque Values

Connector type |

Recommended torque values |

|---|---|

Type-N |

1.1 to 1.7 N·m (12 in. lbs) |

2.4 mm NMD, 3.5 mm NMD, 1.85 mm NMD |

0.8 to 1.0 N·m (8 in. lbs) |

SMA |

0.56 N·m (5 in. lbs) |

CAUTION |

The jumper cables will be damaged if more than 0.9 N·m of torque is applied to their SMA connectors. Do not exceed the permissible torque value. |

CAUTION |

When making and breaking connections, connector mating surfaces should not rotate. Rotate the nut of the male connector only. Avoid rotating the devices. Use a suitable torque wrench. |

CAUTION |

Never cross-thread the connection. Never twist the connector body to make the connection. Never mate the connectors of incompatible types. |

Disconnecting

Disconnect the connectors in the following order:

1. Using the torque wrench used for tightening, loosen the male connector nut while holding the device, or hold the device with an open-end wrench to prevent it from turning.

2. Turn the male connector nut while holding the device so that the connector center conductor remains in the same straight line position as it was connected. Pull the connectors straight apart.